Various industries, including those engaged in the manufacturing, processing, storage, or transportation of flammable materials, as well as commercial centers, heavily rely on a Flame Sensor to ensure safety.

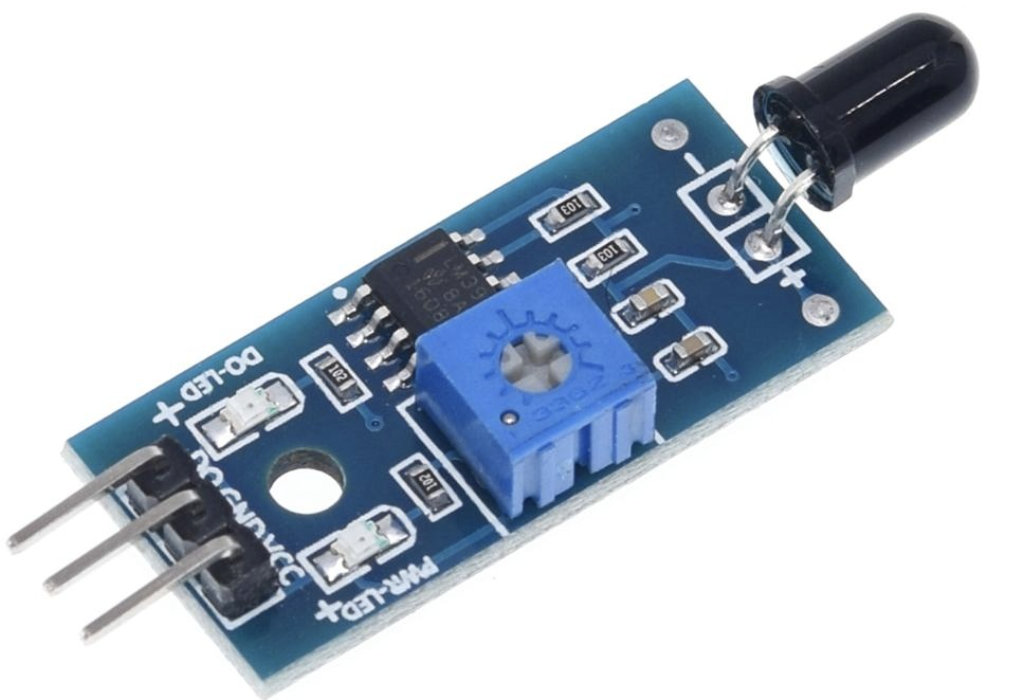

At the heart of this system lies a critical component known as the Flame Sensor. The flame detector is a type of fire detection device that employs optical sensors for its operation. It’s important to stress that the primary purpose of the flame detector is to identify the presence of fire, not merely heat.

This sophisticated device is adept at discerning fire even in scenarios involving smokeless liquids and smoke, which have the potential to ignite. In applications such as boiler furnaces, flame detectors find widespread usage, and they exhibit the capability to detect heat, smoke, and fire.

Furthermore, these devices also take into account factors like air temperature and air movement in their fire detection process. Flame detectors typically employ optical technology, enabling them to swiftly respond to the presence of flames in under a second.

Depending on the specific installation and configuration, a flame detector can trigger an alarm, deactivate the fuel supply, or activate a fire suppression system as needed for enhanced safety.

What are the components of a flame monitoring system? How does a flame detector work?

The primary element of a flame detector system is the flame detector itself, comprising photoelectric detection circuits, signal conditioning circuits, microprocessor systems, I/O circuits, and cooling systems for effective operation.

Within the Flame Sensor, specialized sensors are responsible for detecting the radiation emitted by a flame. These sensors typically employ photoelectric technology to capture the radiant intensity of the flame.

The sensor then translates this radiant intensity signal into a corresponding voltage signal. Subsequently, this signal is further processed within a single-chip microcomputer, ultimately generating an output.

However, during its practical application, there are additional sources of light that emit in the infrared and ultraviolet spectra, which may not be indicative of a fire but can still interfere with the proper functioning of the flame sensor, leading to false alarms.

Instances of these non-fire light sources include phenomena like lightning flashes, welding arcs, metal grinding, hot turbines, reactors, and various other sources.

For homeowners flame sensor ensures safety of your furnace by ensuring no dangerous gas leak or explosion.In most cases,it might be a reason why your furnace won’t turn on or why Home Central Heater Not Working

Types of Flame Detectors.

A variety of flame detectors are currently accessible in the market, each offering distinct features and capabilities. Here, we provide brief descriptions of some key types:

1.Infrared (IR) Detector.

Operating within the infrared spectral band, an infrared (IR) flame detector is designed to detect flames by capturing the specific spectral pattern emitted by hot gases.

In this process, a Thermal Imaging Camera (TIC), which is a type of thermographic camera, is used to sense this infrared radiation.

However, it’s important to note that potential false alarms may occur due to the presence of other hot surfaces and thermal radiation in areas where water and solar energy may obscure the detector’s view.

When considering a Single IR Flame Detector, it’s crucial to understand that its sensitivity typically falls within the range of 4.4 micrometers. Additionally, these detectors exhibit a response time of 3 to 5 seconds, which is a critical factor to consider for effective flame detection.

2.Ultra Violet (UV) Detector.

The Ultra Violet (UV) Detector operates within wavelengths below 300 nm and is specifically designed to identify fires and explosions by detecting UV radiation emitted during ignition, typically within an incredibly rapid 3-4 millisecond time frame.

It’s essential to be aware that false alarms can be triggered by the presence of other UV sources, such as lightning, arc welding, radiation, and sunlight.

To mitigate these false alarms, many UV Flame Detectors incorporate a deliberate time delay of 2-3 seconds into their design.

This delay helps to reduce the likelihood of false alarm activations and ensures that the detector primarily responds to the UV radiation associated with genuine fire or explosion events.

3.Dual (IR / IR) Detector.

he Dual (IR / IR) Detector is an advanced flame detection system that involves the comparison of signals in two different infrared ranges.

To achieve this, it utilizes two sensors with distinct spectral sensitivities. One of these sensors operates within the 4.4-micrometer range, while the other serves as a reference sensor at a different frequency.

By comparing the signal responses from these two sensors, the Dual IR flame detector is capable of enhancing the accuracy of flame detection.

This approach enables the system to discern genuine flame signatures from potential false alarms caused by other sources of infrared radiation.

This dual-sensor design adds an extra layer of reliability and specificity to the flame detection process, making it particularly effective in critical safety applications.

4.The UV / IR Flame Detector.

The UV / IR flame detector is an advanced system that enhances flame detection accuracy by simultaneously comparing signals in two distinct infrared ranges.

This comparison is achieved through both an “AND” configuration and a ratio analysis, which are interrelated to ensure the detection of actual fire events while minimizing the occurrence of false alarms.

By examining the relationship between these two infrared ranges, the UV / IR flame detector can significantly reduce the likelihood of erroneous activations caused by sources other than genuine fires.

This dual-sensor approach, which combines ultraviolet (UV) and infrared (IR) sensing, offers a robust and reliable solution for critical safety applications, making it well-suited for environments where precise fire detection is essential.

5.Triple IR (IR / IR / IR) Detector.

The Triple IR (IR / IR / IR) Detector is an advanced flame detection system that stands out for its high level of precision.

It achieves this by comparing signals from three distinct wavelength bands within the infrared spectrum, and their respective ratios are carefully analyzed to ensure the dependable detection of fires while minimizing the occurrence of false alarms.

By considering these three different wavelength bands and their relationships, the Triple IR flame detector significantly enhances its ability to differentiate real fire events from other sources of infrared radiation, thus offering a superior level of accuracy and reliability in fire detection.

This triple-sensor design makes it an excellent choice for applications where pinpoint accuracy and low false alarm rates are critical.

Selection of a Flame Detector

When choosing a flame detector, several critical factors should be carefully considered to ensure it’s the most suitable option for your specific needs.

The selection process should take into account the following key criteria:

- Nature of Fire: Different types of flame detectors are available, each tailored to specific fire types, such as hydrocarbon fires or hydrogen fires. It’s crucial to select a detector that aligns with the type of fire you want to protect against.

- Protected Area: The size and layout of the area you need to safeguard should influence your choice of flame detector. Consider whether it’s a small, confined space or a large, open environment and select a detector that can effectively cover the entire area.

- Environmental Conditions: Environmental factors like temperature extremes, humidity, and exposure to harsh weather conditions can impact the performance of flame detectors. Ensure the chosen detector can withstand and operate reliably in the prevailing environmental conditions.

- Detector Capabilities: Assess the specific capabilities of the flame detector, including its sensitivity, spectral range, and response time. These features should match your fire detection requirements and objectives.

- Dimensions of the Protected Area: The physical dimensions of the area play a significant role in determining the number and placement of flame detectors. Ensure the selected detectors can adequately cover the entire space for comprehensive protection.

- Radiation Characteristics of the Flame: Understand the unique radiation characteristics of the type of flame you need to detect. Different flames emit radiation in specific spectral bands, and the detector should be capable of sensing these wavelengths.

- Response Time: The response time of the flame detector is critical for timely fire detection and response. Select a detector that offers a rapid response to minimize potential damage or hazards.

- False Alarm Rejection: To maintain system reliability and minimize false alarms, opt for a flame detector with built-in features or configurations designed to reduce false alarm rates, especially in environments prone to sources of spurious radiation.

Installation of a Flame Detector.

The proper installation of a flame detector is crucial, and it should take into account several critical factors:

- Viewing Angle of the Detector: When installing a flame detector, consider the detector’s field of view or viewing angle. Ensure it is positioned to cover the area where flames are likely to occur. The angle at which the detector “sees” potential fire sources is essential for accurate detection.

- Detection Range: The detection range of the flame detector is a key consideration. It should be placed at a distance from the potential fire source that matches its specified range. This ensures that the detector can effectively identify flames within the designated distance.

- Obstructions: Be mindful of obstructions in the installation area, such as beams, girders, or other structural elements. These can block the line of sight between the detector and the fire source. Install the detector in a location where it has an unobstructed view of potential fire hazards.

- High-Risk Fire Ignition Areas: Identify and prioritize high-risk areas where fires are more likely to occur. These areas should receive special attention when positioning flame detectors. Install detectors in places where rapid fire detection is critical for safety and asset protection.

- Mounting Height: Consider the mounting height of the detector. Depending on the environment and application, detectors may need to be positioned at varying heights to ensure comprehensive coverage. Ensure the mounting height aligns with the detector’s design and specifications.

Applications of Flame Detector.

Flame detectors find essential applications in various settings and industries to safeguard against fire incidents. These applications encompass a broad spectrum of environments and scenarios, including:

- Industrial Warehouses: Flame detectors are deployed in industrial warehouses to monitor large storage areas where flammable materials may be present. Early fire detection is critical to prevent substantial property damage and ensure worker safety.

- Chemical Production Plants: In chemical production facilities, flame detectors are employed to detect potential fires during various manufacturing processes, where chemical reactions and volatile materials pose fire risks.

- Chemical Stores: Flame detectors are used in chemical storage facilities to protect against the ignition of hazardous substances. These detectors play a vital role in minimizing the risk of catastrophic accidents.

- Petrol Storage and Pump Stations: Gasoline and fuel storage facilities, as well as fuel pump stations, rely on flame detectors to rapidly detect and respond to fires, preventing explosions and environmental contamination.

- Arc Welding Workshops: Flame detectors are essential in welding workshops, where sparks and open flames are common. They ensure the early detection of welding-related fires.

- Power Plants: The critical infrastructure of power plants is equipped with flame detectors to detect fires that may occur due to electrical faults, fuel sources, or machinery malfunctions, helping maintain uninterrupted power generation.

- Transformer Stations: Flame detectors are utilized in transformer stations to safeguard these critical components of the electrical grid against fire hazards, which could disrupt electricity supply.

- Underground Tunnels: In tunnels, where escape routes may be limited, flame detectors are deployed to detect fires quickly and facilitate rapid emergency responses, protecting the safety of commuters.

- Motor Testbeds: Flame Sensor are used in motor testbeds, where engine testing generates heat and sparks. Detecting fires early is vital to prevent damage to testing equipment.

- Wood Stores: In facilities storing wood and timber products, flame detectors are essential for minimizing the risk of fires, which can lead to substantial losses in the timber industry.

Frequently Asked Questions (FAQs)

What factors should I consider when selecting a flame detector for my facility?

When choosing a Flame Sensor, consider the type of fire you need to detect, the size and environmental conditions of the protected area, the detector’s capabilities, dimensions of the area, flame radiation characteristics, response time, and false alarm rejection features. These factors will help you make an informed selection.

Where should I position the flame detector for optimal performance?

The placement of the Flame Sensor should consider the detector’s viewing angle, detection range, obstructions in the area, high-risk fire ignition areas, and the mounting height. Ensuring an unobstructed line of sight to potential fire sources and aligning the detector with the specific application is essential for its effectiveness.

What are some common applications of flame detectors?

Flame detectors are commonly used in a range of settings, including industrial warehouses, chemical production plants, chemical storage facilities, petrol storage and pump stations, arc welding workshops, power plants, transformer stations, underground tunnels, motor testbeds, and wood storage areas.

These applications cover diverse industries and scenarios where fire safety is crucial.

Can you explain the differences between various types of flame detectors mentioned earlier, such as IR, UV, Dual IR, and Triple IR detectors?

Certainly, different types of Flame Sensor have distinct characteristics. IR detectors operate in the infrared spectrum, UV detectors focus on ultraviolet radiation, Dual IR detectors compare signals in two IR ranges for enhanced accuracy, and Triple IR detectors compare signals from three IR ranges for even greater precision.

Each type has its strengths, and the choice depends on specific fire detection requirements and environmental conditions.

Conclusion.

Flame Sensor are critical components in ensuring fire safety across a wide range of industries and environments. Selecting the right type and positioning them strategically is essential.

These detectors play a vital role in protecting against fires, preventing potential disasters, and maintaining the safety of both people and property.